NewSkin Laser heat treatment of Institute of Metals and Technology (IMT) samples

NewSkin Laser heat treatment of Institute of Metals and Technology (IMT) samples

Published on 26 Jul 16:45 (over 1 year ago) by AquaTTNewSkin collaborator Institute of Metals and Technology (IMT) were successful in applying for a demo-case as part of Open Call 3. The work for which was carried out in NewSkin OITB facilities in Dublin City University (DCU).

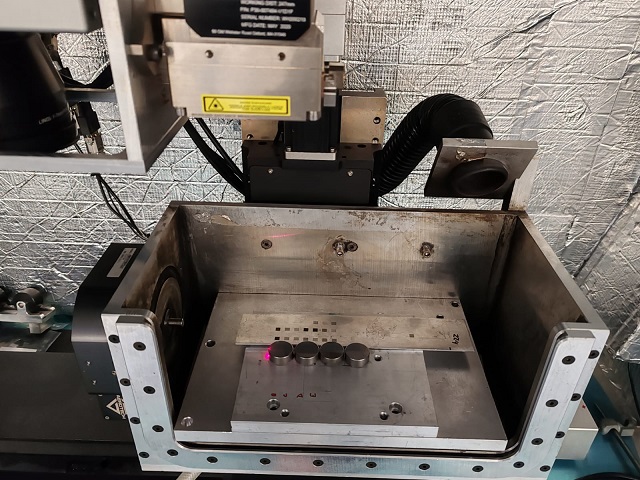

As part of their NewSkin OITB demo-case, laser heat treatment was conducted on four different samples of the coated steel substrate (Figure B below), using a laser to enhance the surface properties. Figure A illustrates the setup of the IPG fiber laser (1 kW, continuous wave laser) utilised for the laser heat treatment of the samples. This laser system can operate along four axes, including a rotational axis. This advanced setup is available at the facilities of NewSkin partner DCU in Dublin (where the team includes Suman Chatterjee, Abhijit Cholkar, Dermot Brabazon, and David Kinahan).

IMT is a public research organisation, with the mission is to create new knowledge in the fields of metallurgy, metallic materials, nanoscience and nanotechnology, vacuum optoelectronics, metrology, engineering materials, environmental protection and to transfer that knowledge to industry. The Institute primarily works in the field of research of metallic materials with an emphasis on research related to steel and aluminium alloys, heat treatment, surface engineering, tribology and materials testing and characterization. Through NewSkin Open Innovation Test Bed the IMT team were able to access the lasers and expertise at DCU to further advance their work.

As part of their NewSkin OITB demo-case, laser heat treatment was conducted on four different samples of the coated steel substrate (Figure B below), using a laser to enhance the surface properties. Figure A illustrates the setup of the IPG fiber laser (1 kW, continuous wave laser) utilised for the laser heat treatment of the samples. This laser system can operate along four axes, including a rotational axis. This advanced setup is available at the facilities of NewSkin partner DCU in Dublin (where the team includes Suman Chatterjee, Abhijit Cholkar, Dermot Brabazon, and David Kinahan).

IMT is a public research organisation, with the mission is to create new knowledge in the fields of metallurgy, metallic materials, nanoscience and nanotechnology, vacuum optoelectronics, metrology, engineering materials, environmental protection and to transfer that knowledge to industry. The Institute primarily works in the field of research of metallic materials with an emphasis on research related to steel and aluminium alloys, heat treatment, surface engineering, tribology and materials testing and characterization. Through NewSkin Open Innovation Test Bed the IMT team were able to access the lasers and expertise at DCU to further advance their work.